The driving motor installed upturned,

protecting the motor damaged from the

grease dropping into the reduction gear.

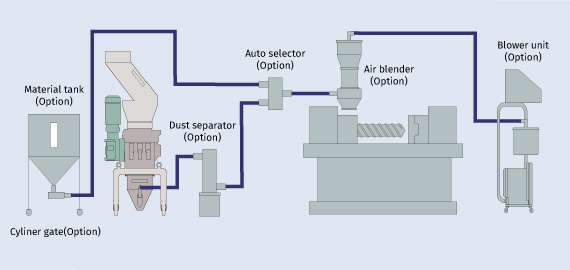

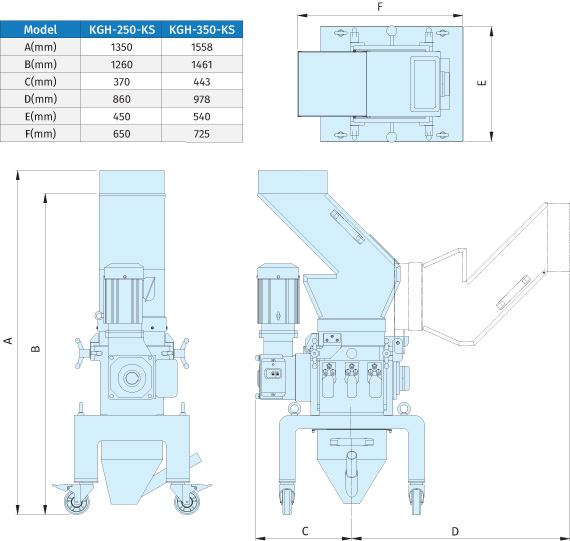

You can put the pump chute in four

positions every 90 degrees.

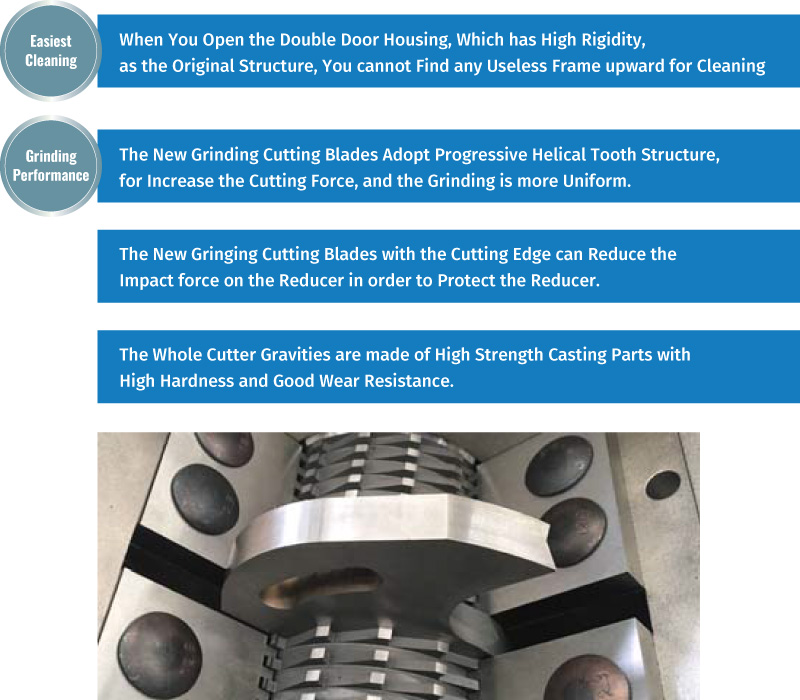

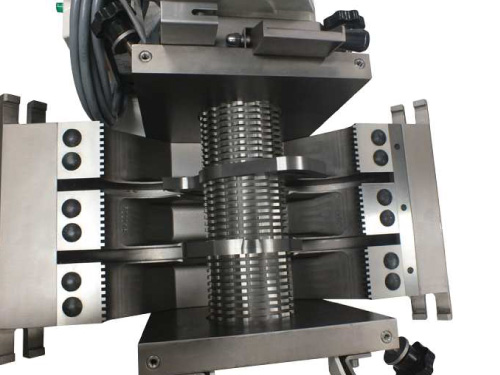

The sealing structure of the cutter cavity can effectively prevent the overflow

of powder when the nozzle material is crushed.

The hopper has a mirror window, and the smashing state is clear at a glance.

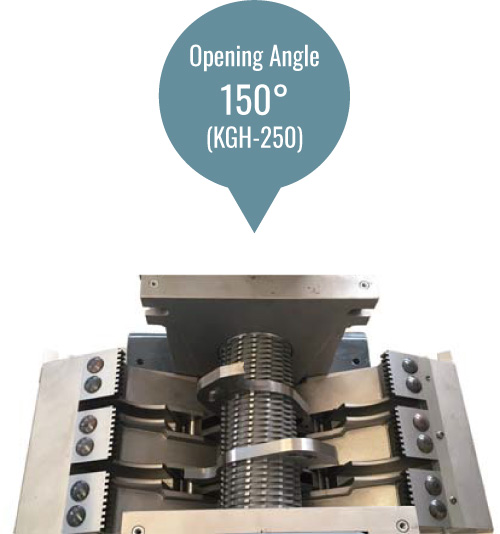

Oilless bearings are used for opening the housing.

The rotary discharge on the ends of the main axis can prevent power from entering the axis.

The fine-scissors of the granulator adopts arc shape design so that the scissors teeth are uneasy to

crack.